11.Dec.2021

11.Dec.2021

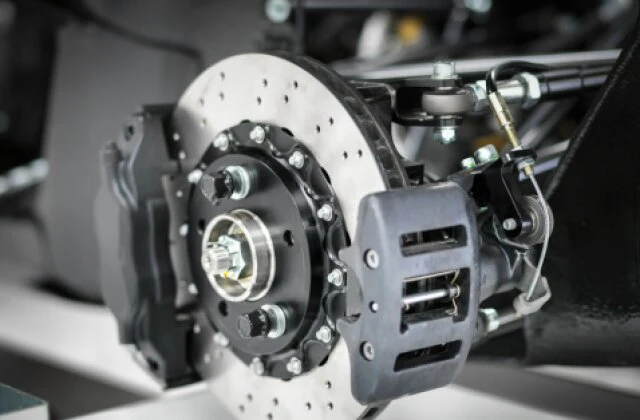

Car Braking System

Although the early designs were entirely mechanical and used levers for control, in the mid-1930s, they were applied hydraulically. The system consists of a master cylinder that provides brake fluid under pressure to the wheel cylinders located in the brake drum.

Importance of Brake Pads

This pressure causes the piston in the cylinder to expand and press the brake pads on the inner side of the brake drum, creating friction, helping to slow the rotation of the wheels. When the brake pedal of a vehicle with hydraulic brakes is pressed on the master cylinder, the piston will eventually press the brake pads on the brake disc, thereby slowing the wheels. If the wheel has a disc brake, the brake fluid activates a piston that causes the caliper with brake pads to press on the disc or rotor connected to the wheel, slowing the vehicle. After braking, the hydraulic pressure in the system is reduced, causing the brake caliper piston to retract.

However, this retraction must consider all the system's flexibility (under pressure) and thermal deformation of components such as the brake disc. Otherwise, the brake system will tighten until contact with the disc, for example, causes it to be repulsed—pads and pistons from rubbing surfaces. The goal is to create as much friction as possible when the brake is applied.

This part must be replaced as soon as a sound is heard during braking or after a specific mileage, provided by the brake pad manufacturer or the vehicle manufacturer. Usually, softer pads that provide better braking need to be replaced after less mileage.

This is due to the brake pads, which, when switched on, rub against the rotors, effectively cleaning themselves. The handbrake system presses the brake pads against the drums in drum brakes. It is located in the center of the accelerator and clutch pedals inside the vehicle.

Working of Hydraulic Brake System

Pressing the brake pedal displaces fluid from the master cylinder through the brake lines to the secondary cylinders on the wheels; the master cylinder has a reservoir that remains full. The hydraulic system multiplies the force of foot on the brake pedal enough to apply the brakes and stop the vehicle. The braking system is used to stop the wheels of a car and thus stop the vehicle.

All systems use hydraulic fluid to operate, and you may need to know how to bleed the brakes yourself for best performance. Unfortunately, brake fluid attracts moisture, which can corrode metal parts of your brake system by lowering the fluid's boiling point, which affects its braking performance. Check the brake fluid in your vehicles frequently and stop at Les Schwab if you notice a drop in fluid level or a leak.

Soft or soft brakes When you apply the brake, you want to feel some resistance—oscillation or vibration when braking. Suppose the steering wheel or vehicle vibrates or vibrates when braking; the rotor thickness may be uneven. Brake lines are steel tubes that start from the master cylinder and go to each of the four brakes on your car's wheels.

One drum brake in front and one rear has only one hydraulic cylinder; the brake with two front blocks has one cylinder for each block and is installed on the front wheels using a drum system. Drum brakes Drum brakes, one front, and one rear shoe have only one hydraulic cylinder; a brake with two front blocks has a cylinder for each block and is installed on the front wheels using a drum system. Disc brakes are the only type used on the car's front, but they can be found on all four wheels. All passenger cars produced and sold in the United States will be equipped with disc brakes at the front or rear, while drum brakes only exist in the rear of American cars.

In terms of brakes, all four wheels of modern vehicles are equipped with hydraulic brakes. Front brakes are considered more important than rear brakes because the car transfers weight to the front wheels when braking. The front brake plays a greater role in stopping the car than the rear brake because the brake transfers the weight of the car forward to the front wheels. When you brake, the front wheels do most of the parking work because all the momentum is transferred to the front wheels.

Instead of pushing a drum to slow the car down, disc brake calipers push the brake pads against a metal disc attached to the wheel. Depressing the pedal further increases fluid pressure and activates the brakes, which slows down the rotation of the wheels and exerts braking forces at the point of contact of the tires with the road. By creating pressure in the system, it forces the brake pads to stop the wheels. When pressure is applied through the hydraulic system, the brake pads are pressed against the brake rotor, causing the vehicle to come to a standstill.

To stop the wheel, friction material in the form of brake pads (installed in a device called a brake caliper) is pressed mechanically, hydraulically, pneumatically or electromagnetically against both sides of the disc. When you drive and depress the brake pedal, this in turn causes the push rod to act on the piston in the master cylinder, which causes the brake fluid to flow into the pressure chamber, which increases the pressure of the hydraulic system. system. The pressure build-up pushes fluid along hydraulic lines to one or more pistons in the caliper, which then apply force to the vehicle's brake pads.

Generally speaking, the components of a hydraulic brake system include brake pedal, master cylinder, wheel cylinder, power brake and brake pipeline. Some high-end or high-performance cars use in-line disc brakes, and some older or smaller cars use drum systems.

This system works with cylinders connected by brake hoses that receive fluids through the brake hydraulic circuit. This hydraulic fluid is sprayed through the tubing to other, larger cylinders located next to the brakes on each wheel. This system consists of a master cylinder that supplies brake fluid under pressure to the brake caliper, forcing its pistons to press against the steel disc of the rotor, creating friction to slow the wheel down. The types of brake booster systems that are used in most vehicles today are designed to increase the pressure the driver puts on the brake pedal.

Most modern passenger cars and light vans use a vacuum booster braking system, which significantly increases the force applied to the vehicle's brakes by the operator. The driver presses the brake pedal and generates force, which is then increased by the engine vacuum. When strong pressure is applied to the brake pedal, the ABS system independently adjusts the speed of each wheel. Eventually, pressing one pedal activates all brakes on all four wheels.